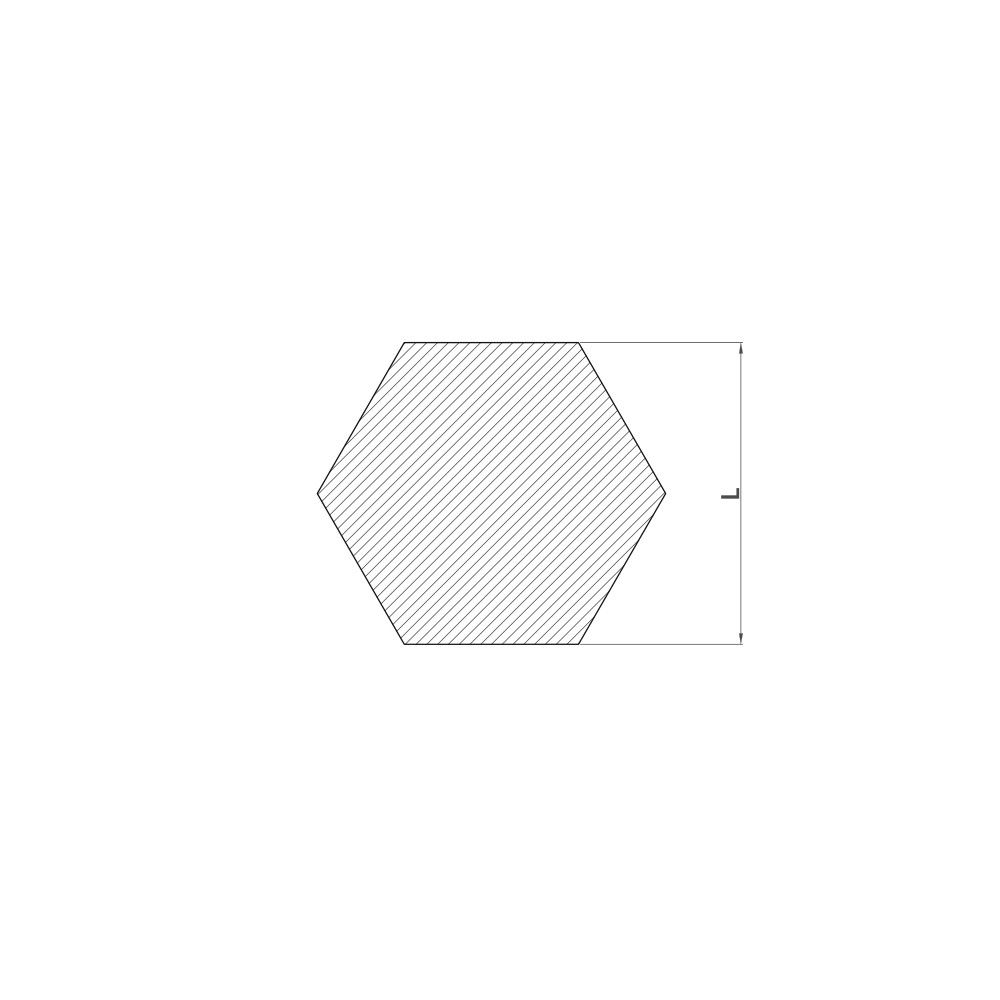

Aluminium hexagonal bar, manufactured in alloy 2011 T3, an alloy with excellent machinability, which enables the manufacture of complex parts by machining.

In calibrated quality, the tolerances of the bar are tighter, which avoids roughing operations depending on the part to be made.