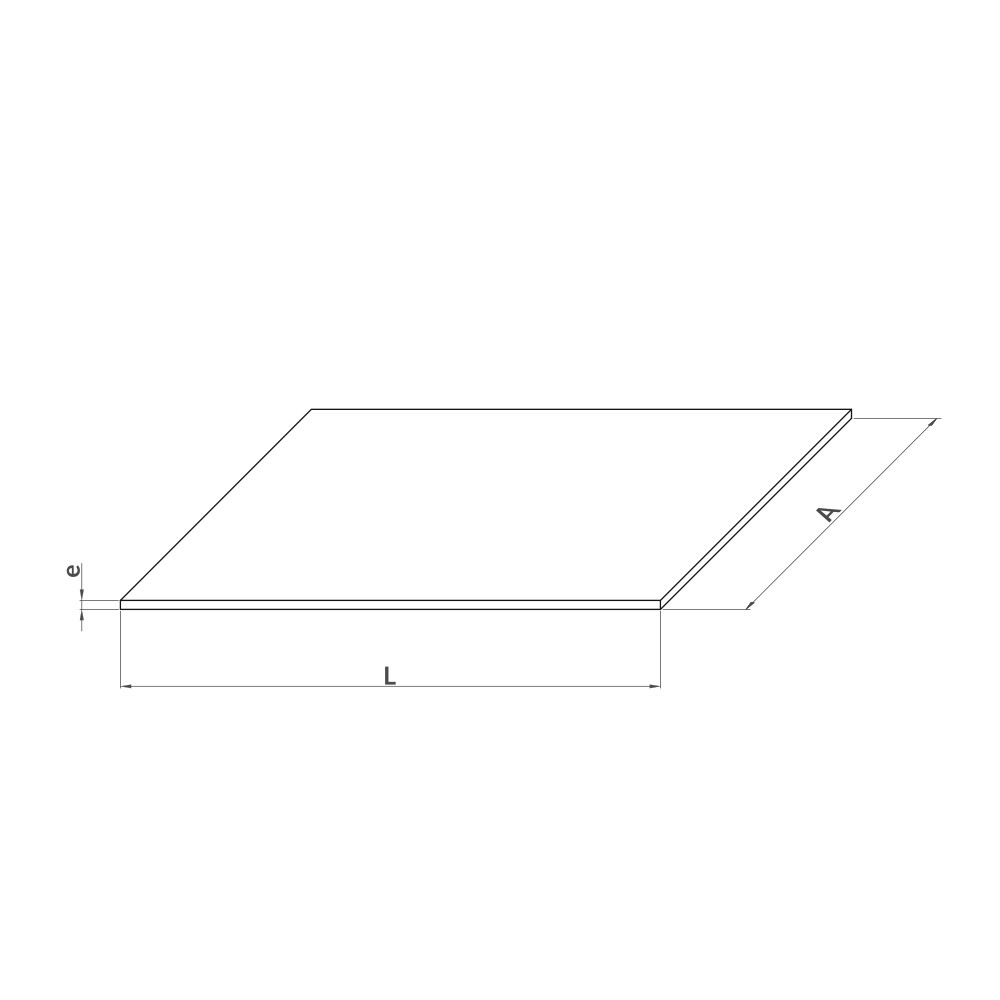

This aluminium sheet with 0.5 mm. thickness is made in alloy 1050 H24 wich main features are these ones:

Composition

The EN AW 1050 aluminium alloy has the following composition under standard EN 573-3:

|

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Ni

|

Zn

|

Ti

|

Others

|

Al

|

|

Indiv.

|

Total

|

|

min

|

|

|

|

|

|

|

|

|

|

|

|

99.50

|

|

max

|

0.25

|

0.40

|

0.05

|

0.05

|

0.05

|

–

|

–

|

0.07

|

0.05

|

0.03

|

|

|

Mechanical properties

The mechanical properties of EN AW 1050 H24 alloy sheets, depending on their thickness and in accordance with standard EN 485-2, are as follows:

|

Condition

|

Nominal thickness mm

|

Rm MPa

|

Rp0.2 MPa

|

A50 mm

Min.

|

A

min. %

|

Bending radius*

|

HBW hardness*

|

|

|

|

min.

|

max.

|

min.

|

max.

|

180

|

90

|

|

H24

|

≥ 0.2

|

0.5

|

105

|

145

|

75

|

|

3

|

|

1.0t

|

0

|

33

|

|

0.5

|

1.5

|

105

|

145

|

75

|

|

4

|

|

1.0t

|

0.5t

|

33

|

|

1.5

|

3.0

|

105

|

145

|

75

|

|

5

|

|

1.0t

|

1.0t

|

33

|

|

3.0

|

6.0

|

105

|

145

|

75

|

|

8

|

|

1.5t

|

1.5t

|

33

|

|

6.0

|

12.5

|

105

|

145

|

75

|

|

8

|

|

|

2.5t

|

33

|

*Reference values for informational purposes.

The difference between the annealed, H18 and H24 states lies in the strength and ductility of the material. The annealed or H111 state is the state with the lowest mechanical strength that the material can have. The H24 state is an intermediate state that balances the strength and transformability of the material and, finally, the H18 state has greater mechanical strength but performs worse in terms of transformability.

Physical properties

The EN AW 1050 alloy has the following physical properties:

|

Elastic modulus

|

Coefficient of expansion per ºC (20º-100ºC)

|

Thermal conductivity

|

Resistivity

µW·cm(2) /cm

|

|

W/mK

|

Cal/cm·s·°C

|

|

68,600 MPa

|

23.5 x 10-6

|

226

|

0.54

|

2.9

|

Technological properties

The general performance of the EN AW 1050 aluminium alloy is as follows in the areas listed below:

– Corrosion resistance: Excellent.

– Weldability: Excellent.

– Formability: Excellent.

– Suitability for anodising: Excellent.

The classification is made in the following range: excellent, very good, good, fair, and poor.

Applications

The main applications of the EN AW 1050 alloy are as follows:

– Containers in the pharmaceutical and food industries.

– Cladding panels and identification plates.

– Electrical conductors.

– Utensils and trays.

– Reflectors.