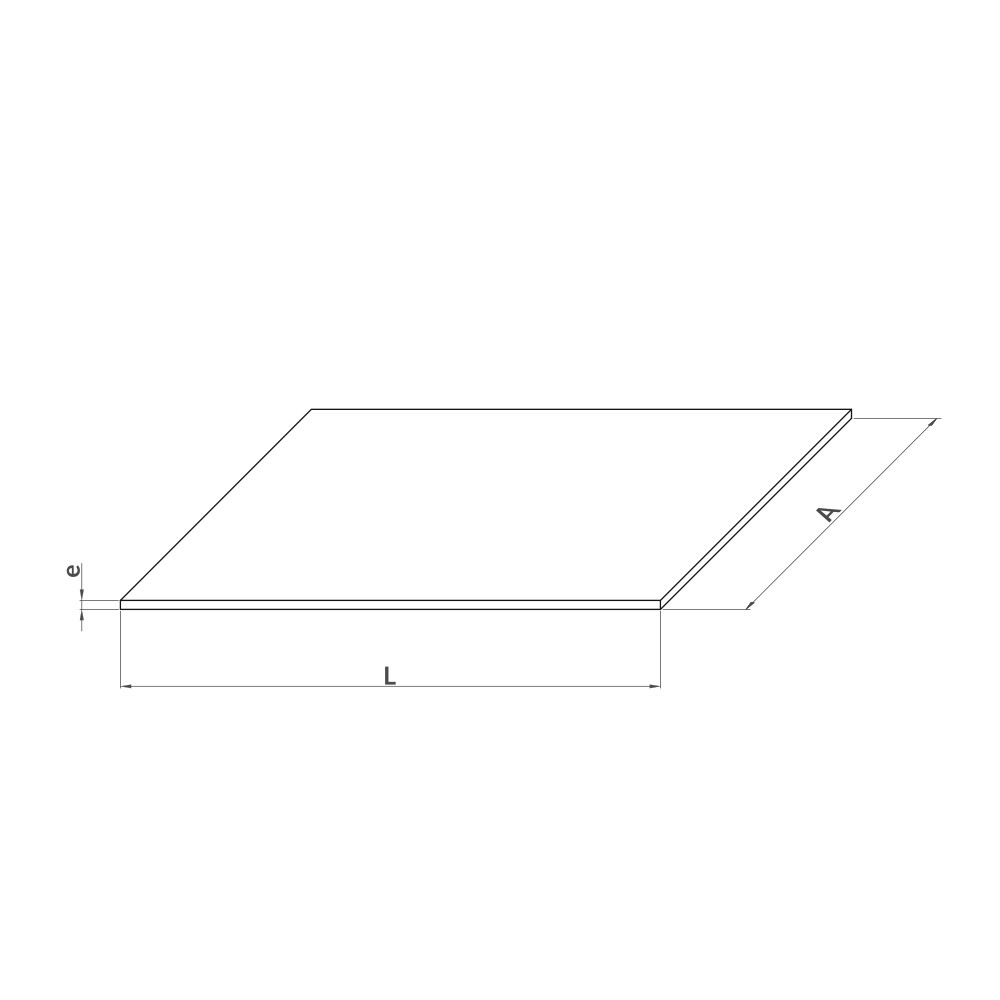

Aluminium sheet made in EN AW 1050 H24 alloy, with high malleability and transformability, in addition to its intrinsic characteristics of lightness and corrosion resistance, it is a recommended option for all types of decorative cladding and similar applications.