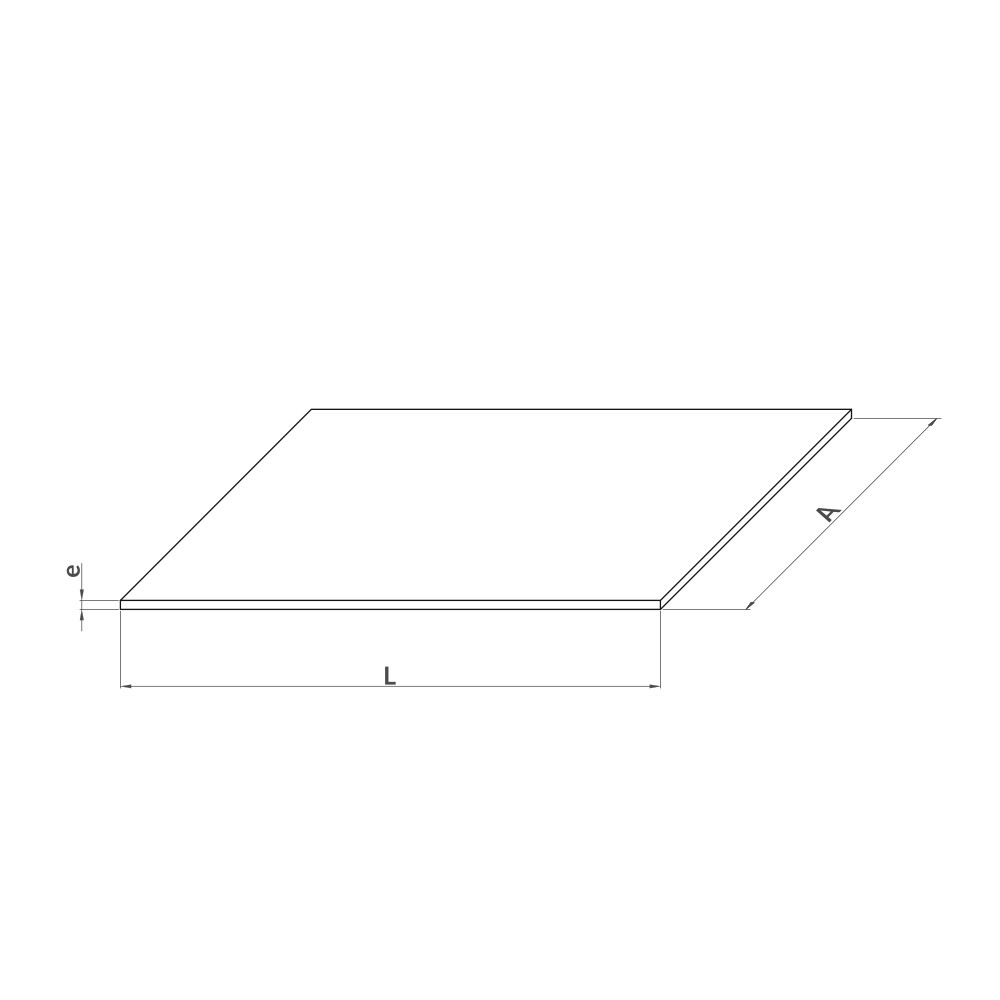

Aluminium sheet made in EN AW 5083 H321 alloy, an alloy with high mechanical strength and excellent corrosion resistance, as well as good weldability. In its H321 state, its corrosion resistance is increased, making it ideal for use in the naval industry. Available with naval certification. Please consult our sales department for specific specifications.