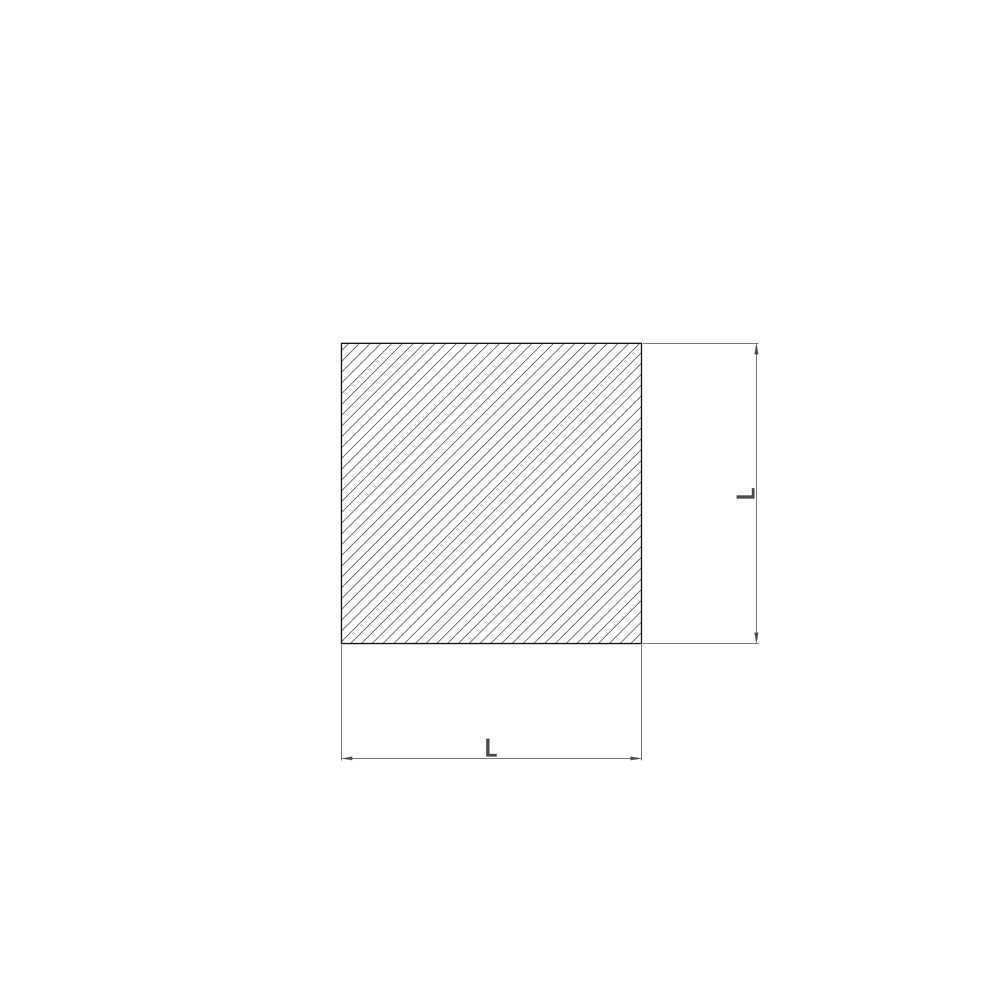

The 30×30 drawn aluminium square bar is made of EN AW 2030 alloy. An aluminium alloy belonging to the 2000 family, with copper as the main alloying element.

It is an alloy with very good machinability, significantly lower than alloy 2011, but with better mechanical characteristics. Like the latter, its lead content, depending on its origin and application, may not comply with RoHS or REACH regulations.

Alloy 2033 is the best alternative for applications where these regulations apply.

Composition

This aluminium alloy has the following composition under standard EN 573-3:

|

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Bi

|

Zn

|

Ti

|

Pb

|

Others

|

Al

|

|

Indiv.

|

Total

|

|

min

|

–

|

–

|

3.3

|

0.20

|

0.50

|

–

|

–

|

–

|

–

|

0.80

|

|

|

|

|

max.

|

0.80

|

0.70

|

4.5

|

1.00

|

1.30

|

0.10

|

0.20

|

0.50

|

0.20

|

1.50

|

0.10

|

0.30

|

Rest

|

Mechanical characteristics

Bars manufactured in EN AW 2030 alloy are supplied in T3 or T4 treatment states depending on the extruded or calibrated quality of the alloy.

Their mechanical properties, in accordance with standards EN 745-2 and 755-2, are as follows:

|

Condition

|

Main measurement mm

|

Rm MPa

|

Rp0.2 MPa

|

A

min.

|

A50 mm

min.

|

HBW hardness*

|

|

min.

|

Max.

|

min.

|

Max.

|

|

T3

|

≤ 30

|

370

|

–

|

240

|

–

|

7

|

5

|

115

|

|

30 < d ≤ 80

|

340

|

–

|

220

|

–

|

6

|

–

|

115

|

|

Q4

|

≤ 80

|

370

|

–

|

250

|

–

|

8

|

6

|

115

|

|

80 < d ≤ 200

|

340

|

–

|

220

|

–

|

8

|

–

|

115

|

|

200 < d ≤ 250

|

330

|

–

|

210

|

–

|

7

|

–

|

115

|

*Reference value for informational purposes.

Physical properties

The EN AW 2030 alloy has the following physical properties:

|

Elastic modulus

|

Coefficient of expansion per °C (20°-100°C)

|

Thermal conductivity

|

Resistivity

µW·cm(2) /cm

|

|

W/mK

|

Cal/cm·s·°C

|

|

72,600 MPa

|

23 x 10-6

|

146 (T4)

|

0.35 (T4)

|

5.0 (T4)

|

Technological properties

The general behaviour of the EN AW 2030 aluminium alloy is as follows in the areas listed below:

– Corrosion resistance: Low.

– Weldability: Low.

– Machinability: Excellent.

– Formability: Fair.

– Suitability for anodising: Low.

The classification is made in the following range: excellent, very good, good, fair and low.

Applications

The main applications of the EN AW 2030 alloy are as follows:

– Parts of medium-high complexity and high mechanical characteristics requirements without corrosion constraints.