Falkit® System installation

Construction details

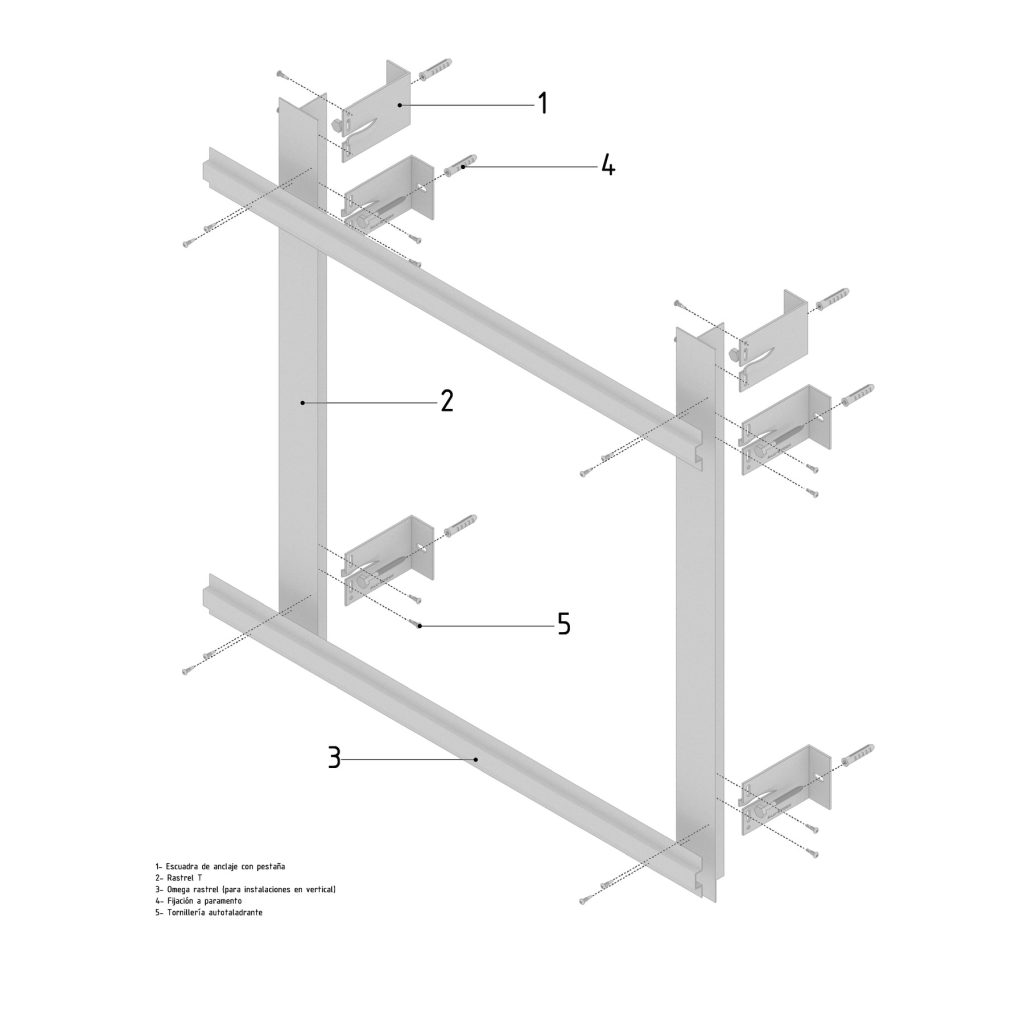

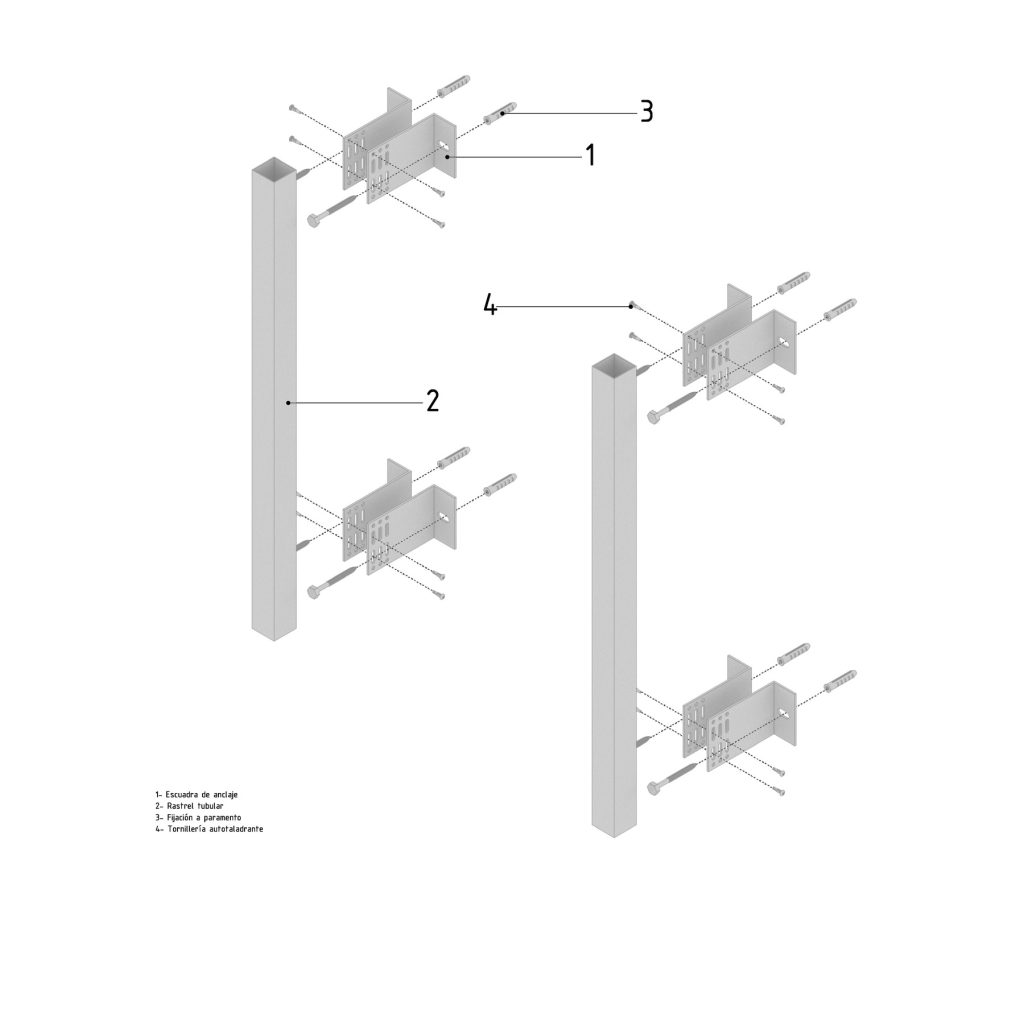

ECP substructure

The ECP substructure is designed for installations requiring insulation and a ventilated chamber. Depths of up to 150 mm can be achieved. The anchoring bracket with flange allows adjustment of the strip before final fixing.

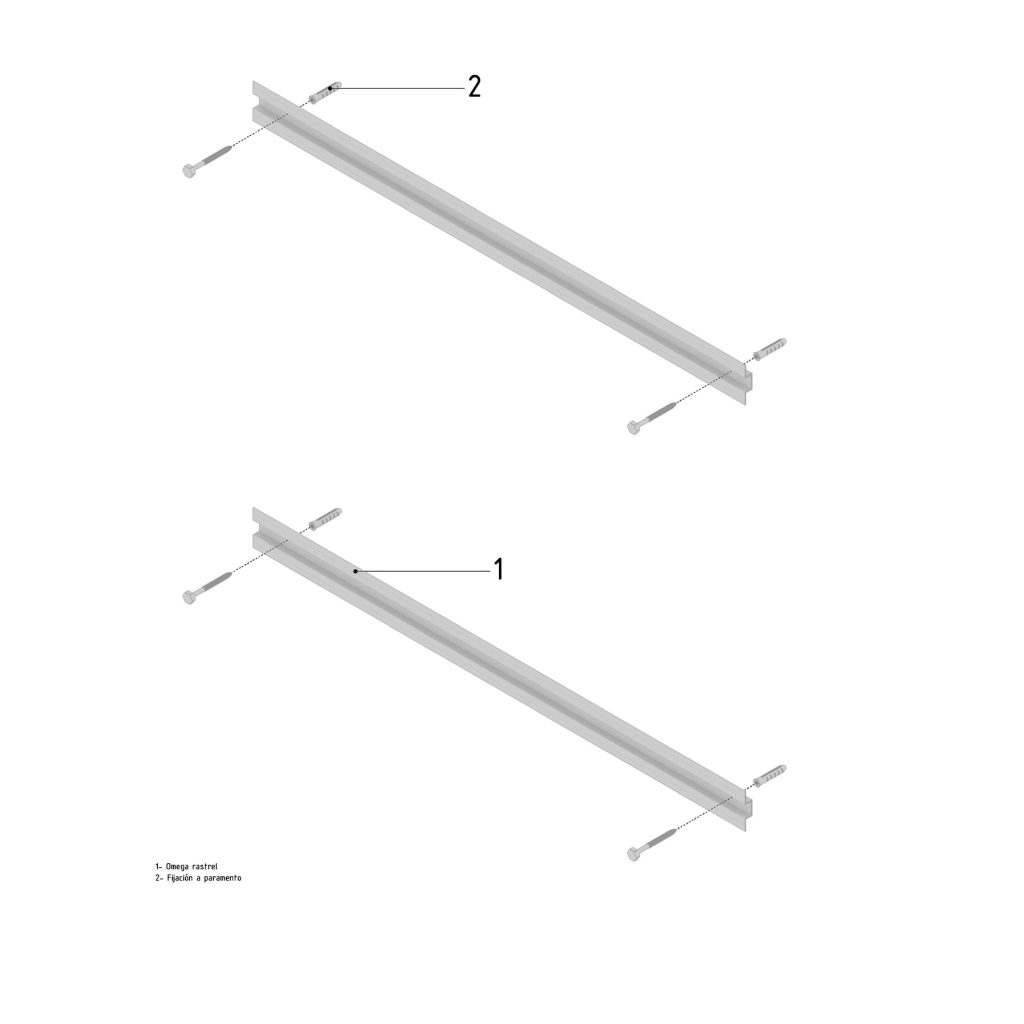

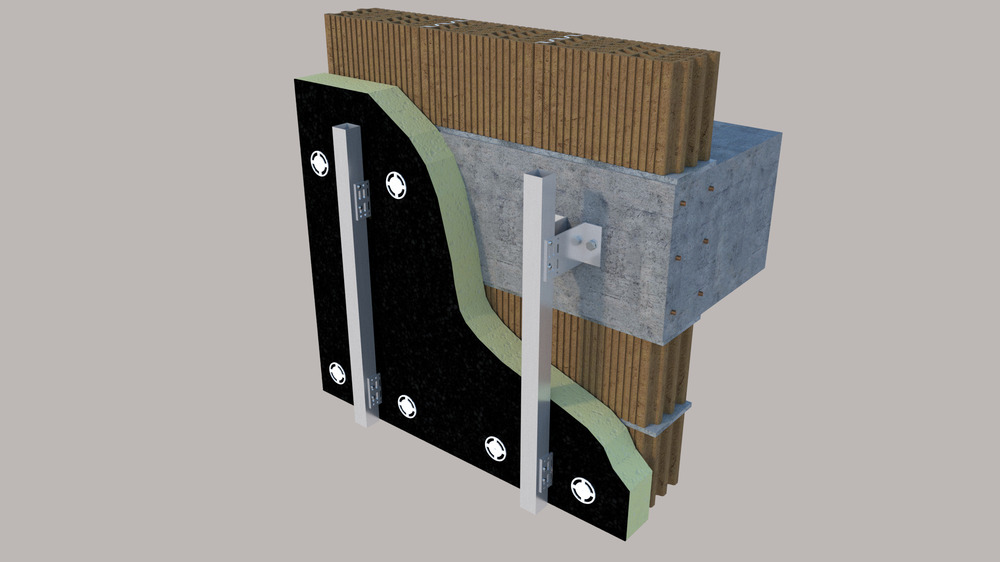

OM substructure

The OM substructure is designed for walls with optimum regularity and requiring neither insulation nor a ventilation chamber. Ideal for indoor use.

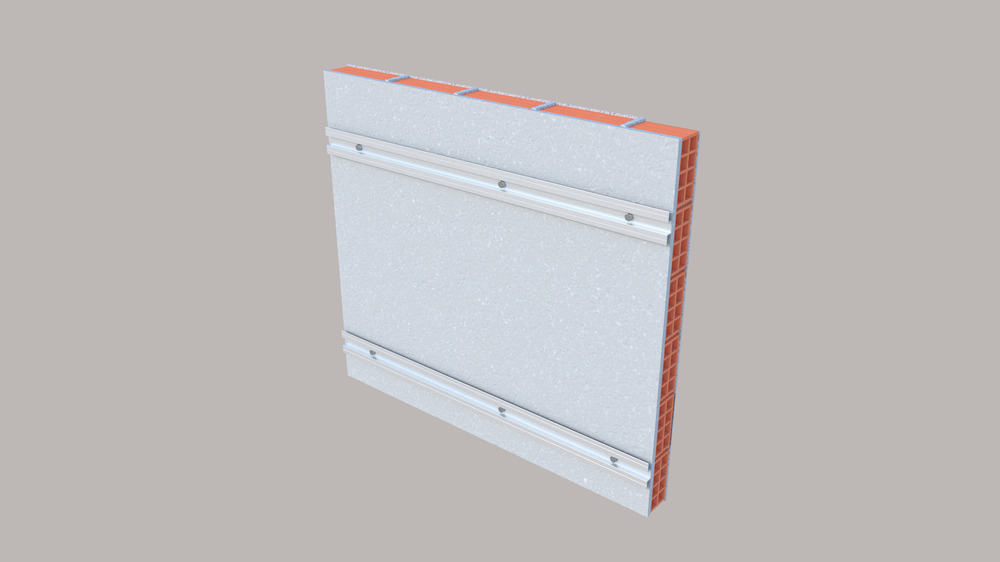

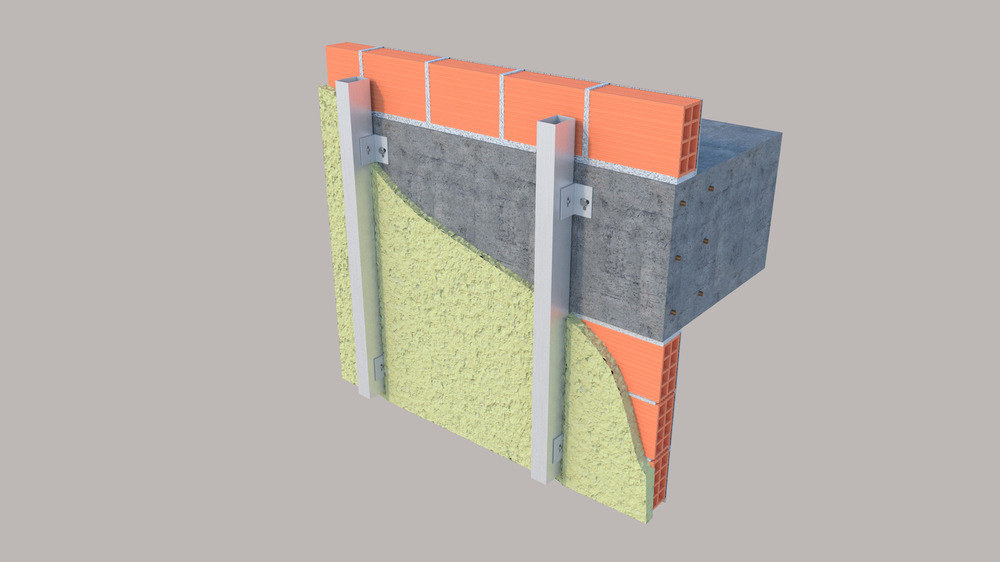

BA substructure

The BA substructure is designed for cladding where insulation is not to be installed or is not an essential element, but optimum ventilation chambers are required.

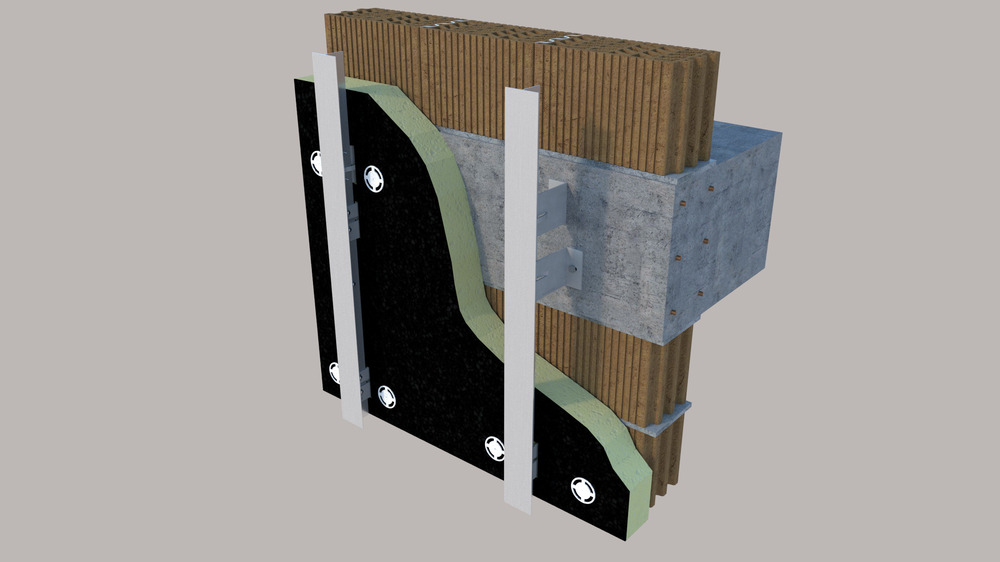

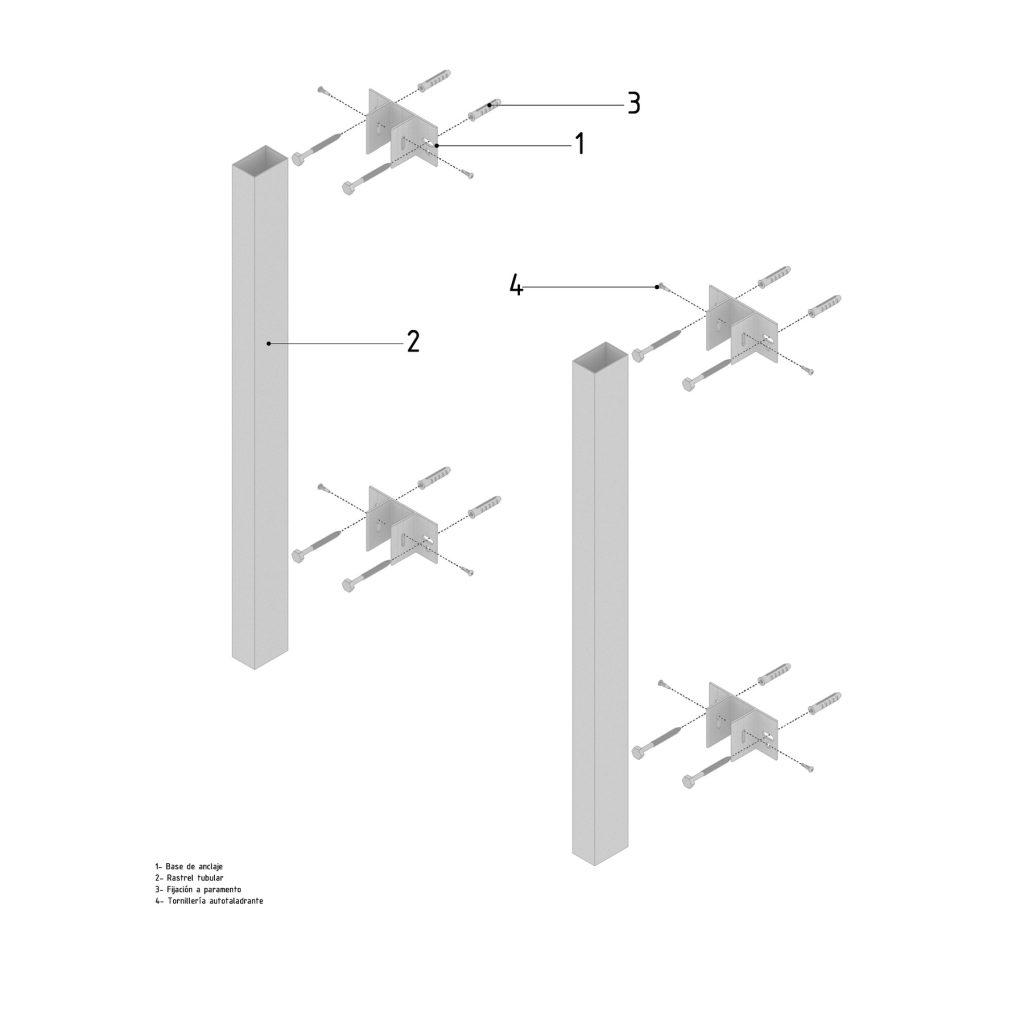

ET substructure

The ET substructure is designed for installations requiring insulation and a ventilated chamber. The different elements can be adapted to different installations both in depth and width and allow the size of the tubular strip to be optimised.

Falkit System installation

The modulation of the Falkit slats enables them to be installed in both large and small panels. The system has starting and finishing profiles that can be adapted to the different possible installations, also combining the flexibility of mouldings made of folded sheet metal, as well as a wide range of standard profiles that enable the system to be finished off at any meeting point.

We offer technical assistance to solve the different construction details of joints and finishes that may arise in projects. Contact us:

Maintenance and cleaning

Aluminium is a material that requires minimal maintenance and is very easy to maintain. The following are recommendations for cleaning and maintenance depending on the finish in order to maintain a long-lasting finish and performance over time.

Products to avoid

In any case, acidic or alkaline cleaning agents and abrasive cleaning agents should be avoided. Also, prior to installation and during assembly, it is important to protect the product from possible stains from other products such as lime, cement or concrete. These products have the ability to attack the anodic layer and must be removed immediately.

Interiors

In general, for proper maintenance and cleaning of indoor aluminium products, periodic cleaning with soft cloths and, in some cases, neutral cleaning agents rinsed with water will suffice.

Anodised aluminium

Anodised aluminium by its nature has excellent resistance to corrosion and discolouration, however, its finish can be altered by external agents or conditions. Commonly, soiling only causes aesthetic deterioration without compromising the excellent stability of the product.

In cases of stubborn dirt, it is possible to apply neutral cleaning agents with finely distributed abrasive elements in the product, which do not affect the aluminium surface chemically or mechanically.

Exteriors

Outdoor cleaning will depend on the exposure and aggressiveness of the environment in which the products are installed. In general, the aim is to avoid deposits of residues and stagnant dirt that can cause corrosion together with ambient humidity. Periodic cleaning with water may be sufficient for this purpose.

For more stubborn dirt, neutral cleaners can be used. Also, without functionally affecting the assembly and avoiding deep water penetration as far as possible, pressure water cleaning machines can be used.

Any cleaning agent residue must be removed with clean water afterwards.

Lacquered aluminium

Aluminium is lacquered according to processes that ensure its correct corrosion behaviour.

In the case of lacquered aluminium, any type of abrasive product that may irreparably damage the lacquer must be avoided. Car cleaning detergents can be used according to the manufacturer’s instructions.