Aluminium for Industry

Aluskit® modular profiles

The Aluskit® System is a system of modular profiling and its corresponding accessories designed for assembling all types of structures. From structures mainly for industrial use to others with decorative characteristics, the versatility of the system allows for the construction of multiple assemblies.

Examples of application: view sample images

- Stands and other types of temporary architecture

- Furniture: shelves, desks, auxiliary structures,…

- Structures for attaching solar panels

- Signs and posters

- Perimeter fences

-…

The lightness of the profiles, especially compared to steel, and its modular capacity, achieved mainly due to the large number of accessories available, make this system a highly versatile solution for any type of assembly. The use of T-channels in the profiles allows any type of connection and a large assembly/disassembly capacity in a simple way, without any welding. In addition, the anodised finish of the profiles gives both aesthetic and corrosion protection characteristics.

- Finish, supply and accessories

- Technical characteristics

- Structures

Series | The extensive range of profiles is divided into four series differentiated by the main measurement of the profiles as well as by the channel used.

Finish | The profiles in stock are available in 15 μm natural anodised finish and in lengths of 6,050 mm. On request and subject to a minimum quantity, we can supply the profiles in other finishes, both anodised and lacquered, and rough, as well as in a variety of lengths.

Supply | We offer a cut to size service for our profiles, as well as the machining necessary to insert accessories and for threading of the inner ribs, if required.

Accessories | The wide range of modular profiles is in turn complemented by a wide range of accessories that make it possible to create multiple connections and assemblies. We offer a wide variety of materials depending on the assembly to be carried out, in zinc-plated steel for indoor connections and in aluminium or stainless steel for connections in outdoor or highly corrosive environments. See the Accessories section to view the fittings available.

Technical characteristics | Aluskit® System profiles are extruded in EN AW 6106 alloy and they have T5 open-air tempering and artificial maturation treatment. This alloy has better characteristics than EN AW 6063 ally with the same extrudability, which makes it possible to create profiles in a wide variety of shapes and with high strength.

| Yield Strength Rp 0.2 (MPa) |

Tensile strength Rm (MPa) |

Tensile strength at shear Rg (MPa) |

Elongation after rupture A5 (%) |

Hardness HB |

|---|---|---|---|---|

| 190 | 225 | 140 | 14 | 75 |

The physical characteristics common in practice to all aluminium alloys are:

| Young’s Modulus E (MPa) |

Transverse modulus of elasticity G (MPa) |

Density (kg/dm3) |

Thermal expansion coefficient |

|---|---|---|---|

| 70,000 | 27,000 | 2.7 | 2.4 x 10-6 K |

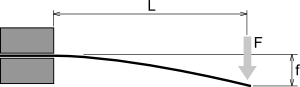

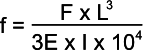

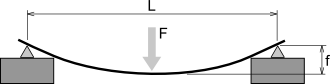

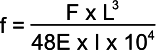

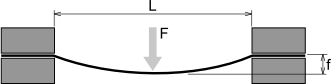

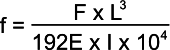

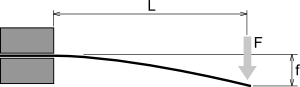

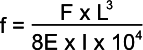

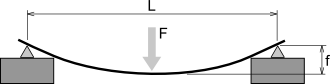

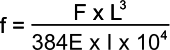

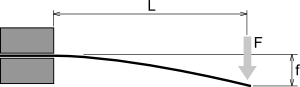

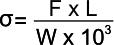

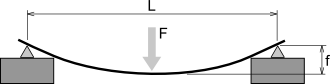

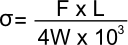

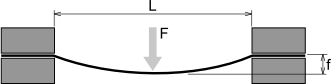

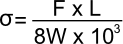

Structures | To calculate the deformation and stress to which the profiles will be subjected the following formulas are used depending on the type of structure:

| Calculation of deflection of beam subjected to stress | |

|---|---|

|

|

|

|

|

|

| Calculation of deflection in beam from its own weight | |

|---|---|

|

|

|

|

|

|

| Calculation of bending stress | |

|---|---|

|

|

|

|

|

|

Maximum stress allowed: σmax < 200 N/mm2.

Formulas where:

F = Force exerted (N)

L = Length of material (mm)

I = Modulus of inertia in the direction of the stress (cm4)

W = Moment of resistance (cm3)

f = deflection (mm)

σ = Tension produced by the stress (MPa = N/mm2)

Other products | Our capacity in terms of supply allows us to design tailored solutions if customers cannot find the profiles they require in this catalogue. We are at your disposal to advise you in the design and assembly of your structure.