Lead free aluminium bars

lead free alloy 2033

The 2033 Lead-Free alloy has many potential applications; it is highly machinable due to its fine chip formation, high mechanical properties and comparatively better anodizing and soldering capabilities than other alloys such as 2011, 2007 or 2030.

Alloy 2033 Lead-Free is the alternative to alloys 2011, 2007 or 2030.

It is a tin-free alloy, which avoids the fragility that this element brings to the material and also the weakening or breakage of machined parts when subjected to fatigue or extreme temperatures (< -13ºC or > 160ºC).

Its main applications are in the following sectors: automotive, electrical and electronic industry, precision machining, defence, forging, screws, nuts, threaded parts…

Chemical composition

| E | Si | Fe | Cu | Mn | Mg | Cr | Ti | Zn | Bi | Ni | Other indiv. | Other Conj. | Rest |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | 0,1 | 2,2 | 0,4 | 0,2 | 0,05 | ||||||||

| Max. | 1,2 | 0,7 | 2,7 | 1,0 | 0,6 | 0,15 | 0,1 | 0,5 | 0,8 | 0,15 | 0,05 | 0,15 | Al |

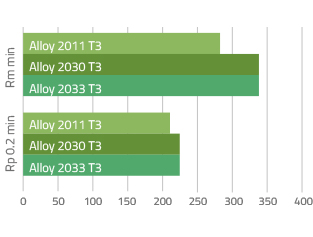

Mechanical Properties

The following is a comparison of the mechanical characteristics of the alloys 2033 Lead-Free, 2011 and 2007/2030.

*The data shown refers to calibrated bars and diameters less than 80 mm. Data may vary depending on condition and diameter.

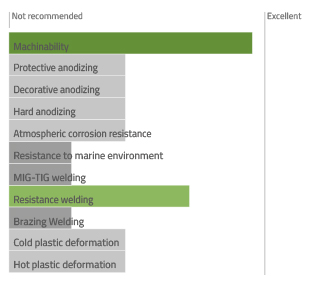

Response

The qualitative assessments of the alloy behaviour in different parameters for the

T3/T6 state are detailed below..